E: enquiry@technicut.co.uk

With the wide spectrum of materials used in airframe manufacture including aluminium, composites and titanium, Technicut manufactures a wide suite of optimised tooling in carbide, diamond coated and polycrystalline diamond (PCD) derivates for Hole Production, Edging, Trimming and Surface Generation applications.

An extensive range of high performance drills for all airframe hole production requirements. Manufactured in both HSS, Carbide, Diamond and PCD derivatives, our optimised drills provide outstanding hole quality with guaranteed process security.

Our range of HSS, Carbide, Diamond and PCD Countersinks are available with different flute configurations depending on customer specific application. Our countersinks are manufactured to the highest standard to guarantee concentricity with your hole.

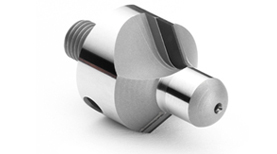

Highly accurate Carbide, Diamond and PCD UHR Cutters are available for radius machining of airframe components and can be provided with both threaded and straight shank configurations.

A comprehensive range of HSS, Carbide, Diamond and PCD reamers are available for your specific application and are fully optimised to provide outstanding hole quality.

High precision one-shot drill countersinks are available in both HSS, Carbide, Diamond and PCD configurations, enabling a one shot pass to drill and ream the hole and apply a countersink to finish.

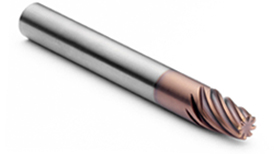

Technicut provides Carbide, Diamond and PCD Routers for all your edge of part machining requirements. Optimal configurations of flute density and length are available for your specific component/material application.

Carbide, Diamond and PCD Ball Nose Cutters provide economical solutions for surface machining requirements. All of Technicut's Ball Nose Cutters are application optimised to provide guaranteed surface finish with enhanced productivity and minimised cost of part.

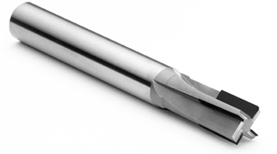

Technicut's Carbide, Diamond and PCD Sturtz Cutters generate extremely high MRR's utilising enhanced linear feed rates and through increased tool longevity generate lower cost component surface acquisition.

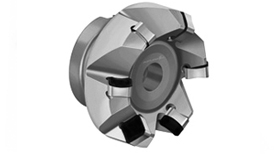

Technicut's PCD FaceMill Cutters are optimised for fibre reinforced composite applications to provide superior surface finish with zero delamination.